JENNMAR

contact usOur Portfolio of Brands

Our Brands, Our Strength

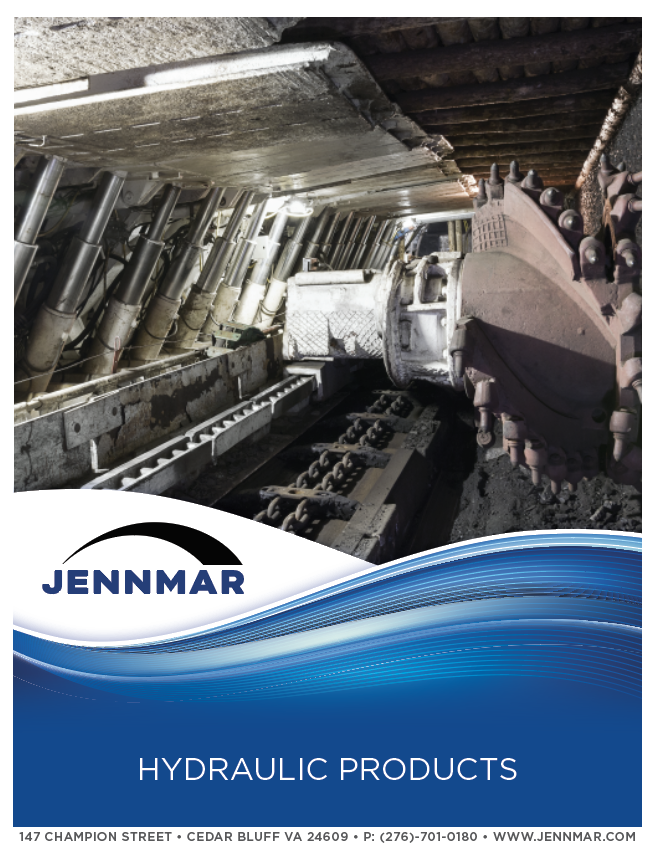

JENNMAR designs and manufactures a wide range of dependable ground control products, from bolts and beams to channels and trusses, resin, rebar, and more. We’re proud to make products that make the mining, tunneling, civil, and construction industries safer and more efficient.

Because we understand the ever-changing and demanding conditions above and below ground we have built the richest portfolio of diverse and complementary brands. JENNMAR sets the bar in every industry we serve and as we continue to grow, our focus will always be on the customer.

We feel it is essential to develop a close working relationship with every customer so we can understand their unique challenges and ensure superior customer service. Our commitment to the customer is guided by three words: SAFETY, SERVICE, and INNOVATION. It’s these words that form the foundation of our business. It’s who we are.

For a complete list of our portfolio of brands, visit our Affiliates page.

Serving Industries That Make Modern Life Possible

At JENNMAR we consider safety to be a core value. Safety starts with our people and transfers through our products and services to our clients. The products and services we provide are designed to enhance the safety of the people working in a vast range of industries:

- Agriculture

- Logistics

- Civil

- Chemical

- Construction

- Geotechnical

- Infrastructure

- Forestry

- Manufacturing

- Mining

- Fabrication

- Recruitment

- Safety

- Steel

Explore Our Products

From bolts and beams to channels and trusses, to resin and rebar, JENNMAR is proud to manufacture products that make Coal & Hard Rock Mining, Tunneling, Civil, and Construction safer and more efficient.